RF-25 6/1

AUTOMATIC MACHINE FOR FILLING AND CAPPING BOTTLES AND RIGID CONTAINERS WITH NARROW MOUTHS, IT IS IDEAL FOR DOSES OF UP TO 250 CC.

EQUIPEMENT

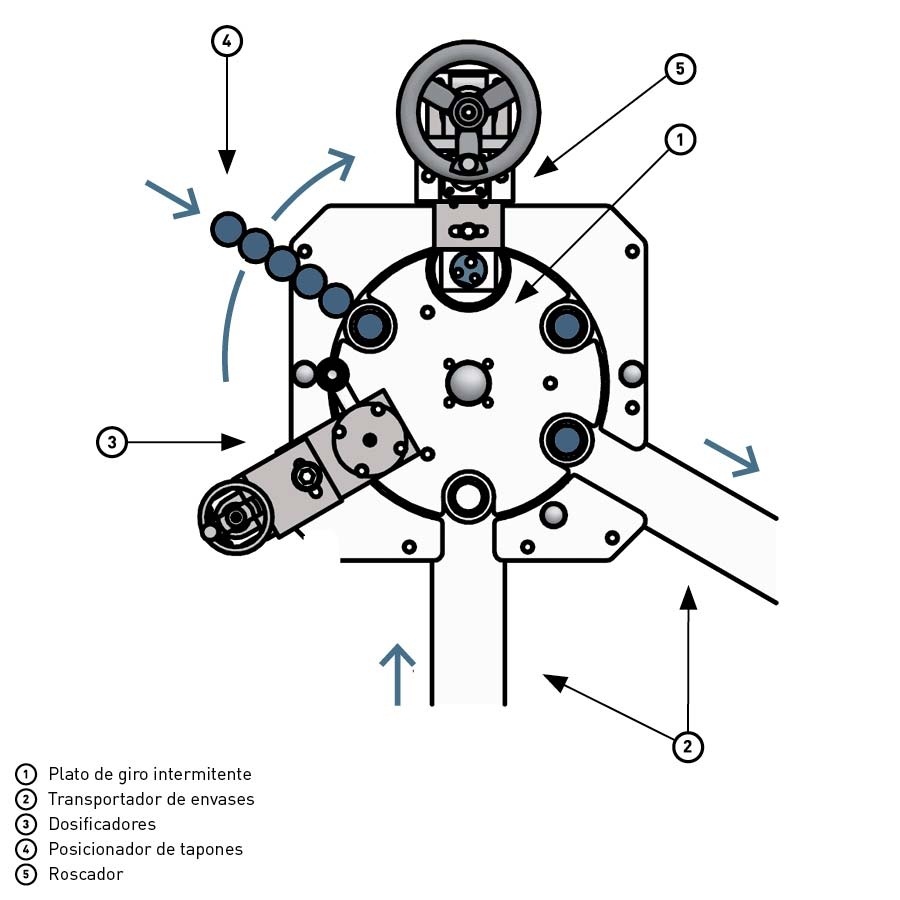

· Intermittent rotary unit with star plate with 6 stations for container movement.

· Powered conveyor for pulling the container into the star plate.

· Filling unit equipped with pump and impulse generator to select dose from the electronic counter.

· Anti-drip nozzle for liquid products with easy-install washing collector.

· Product suction directly from the product container.

· Ramp for the direction and positioning of caps at the capping unit.

· Positioner of caps on the container to be closed.

· Capping unit by means of a pneumatic gear motor with adjustable pressure.

· Powered conveyor for extraction of containers from inside the machine.

OPTIONAL EQUIPEMENT

· Accumulation table for automatic feed of empty containers inside the machine..

· Accumulation table for automatic feed of filled containers at the end of the exit conveyor.

· Labelling heads for self adhesive labels

· Expiry date and code marker.

· Induction sealing system for aluminium lids.

· Preinstallation for synchronization with C.I.P. system.

· Exchangeable format kits for bottling containers with different volumes.

· Automatic cap and unit feeders for a high level of autonomy.

· Laminar flow cabinet.

· Ability to seal with pressure, screw or pilfer proof caps, among others.

TECHNICAL FEATURES

Height 1.700 mm

Width 1.670 mm

Length 1.550 mm

Weight 350 Kg

Power supply Three-phase 380V + neutral

Pneumatic supply 6 bar

Filling capacity for containers of 10 > 60 mm Ø

Capacity Up to 1.000 containers

Download our catalogue